Power Generation

In the power generation industry, reliable and high-performance valves are essential to control steam, gas, and water flow across various systems. VALTEK (Shanghai) offers a wide range of power plant valves engineered for high-temperature, high-pressure, and continuous operation environments. Our stainless steel and carbon steel valve solutions, including ball valves, globe valves, gate valves, check valves, and butterfly valves, ensure long-term durability, leak-tight sealing, and operational safety in thermal, hydro, biomass, and nuclear power generation sites.

Power Plant Industry

High-Temperature and High-Pressure Valve DemandsPower plant systems operate under extreme conditions, where steam valves and high-temperature valves must manage aggressive media, rapid pressure fluctuations, and intense heat cycles. In these applications, precision flow control and safety are critical. VALTEK power generation valves are designed to withstand these challenges, delivering stable performance, minimal maintenance, and extended service life to support the efficiency and uptime of power generation facilities.

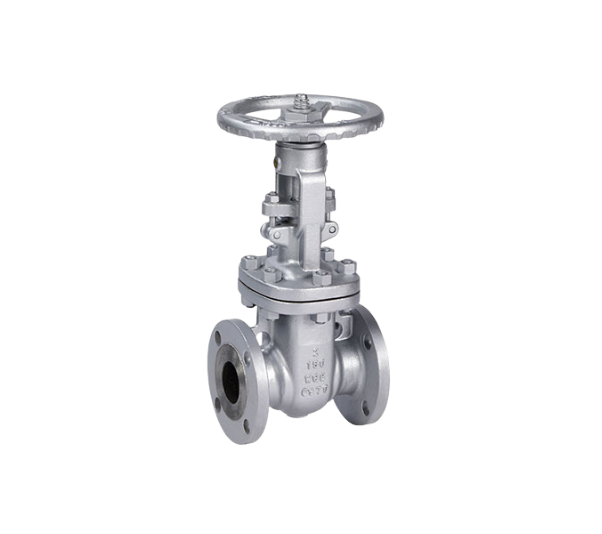

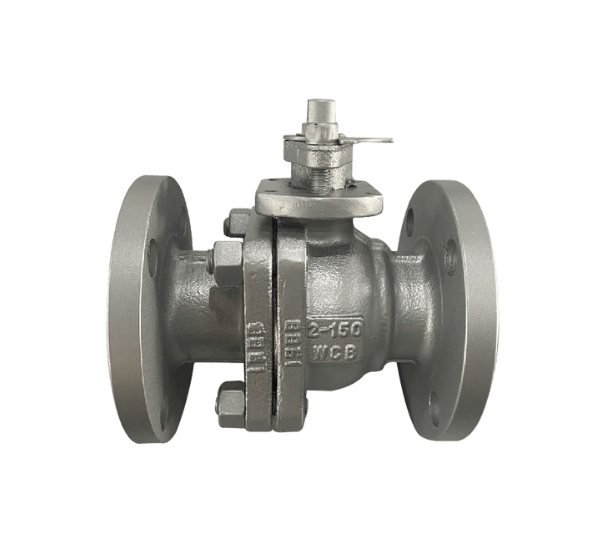

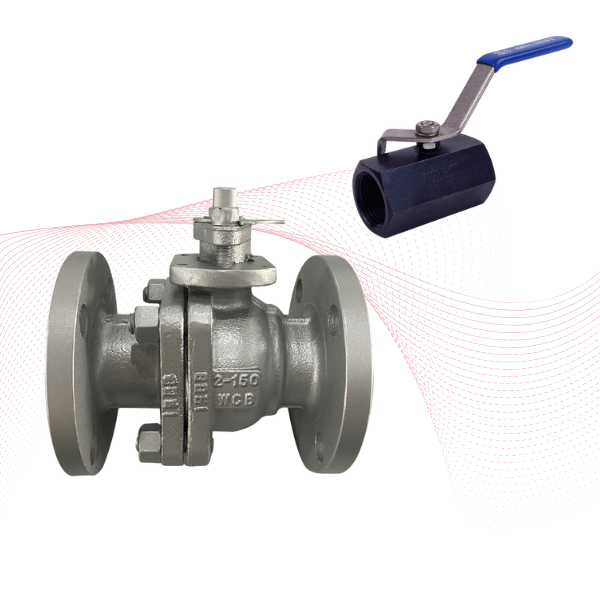

Carbon Valves (WCB)

VALTEK Solutions for Process ControlCarbon steel valves made from ASTM A216 WCB are widely used in power plant systems due to their excellent resistance to high temperatures and working pressures. Ideal for handling steam and water circuits, these valves are reliable components in turbine systems, heat recovery loops, and main steam pipelines across various power generation industries.

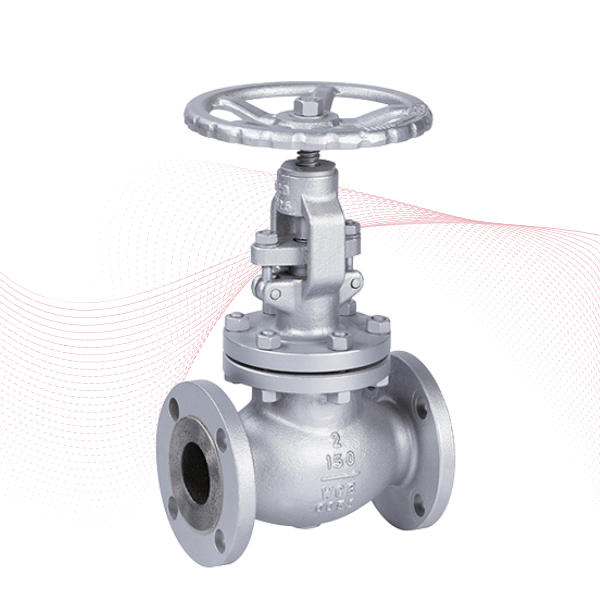

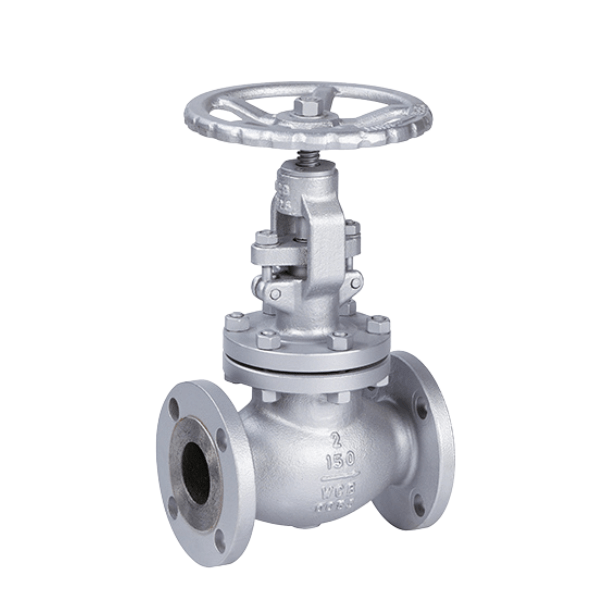

Carbon Globe Valve

VALTEK Solutions for Process ControlVALTEK's carbon steel globe valves provide precise flow regulation in demanding steam applications. They are commonly installed in boiler control systems, turbine bypass stations, and high-pressure feedwater lines. These power plant valves ensure accurate throttling, tight shut-off, and long service life—making them a trusted solution for power generation sites focused on safety and efficiency.