Renewable Energy

In today's transition to clean energy, valves for renewable energy systems play a vital role in managing fluid and gas flow across solar, wind, geothermal, and hydrogen applications. VALTEK (Shanghai) offers a complete range of stainless steel valves for solar and wind power, engineered for corrosion resistance, low maintenance, and energy efficiency. From solar thermal systems to hydrogen electrolyzers, our valve solutions for clean energy plants help maximize output and ensure operational reliability. As a trusted industrial valve supplier for renewable energy plants, we are committed to supporting global decarbonization goals with durable and dependable flow control solutions.

Renewable Energy Sector

Sustainable Flow Control for Solar, Wind, and Hydrogen EnergyThe renewable energy industry demands high-performance valves that can withstand aggressive outdoor conditions, variable temperatures, and corrosive media. In solar and wind power valve systems, stainless steel materials are essential for longevity and resistance to harsh environments. For hydrogen energy valves, zero-leakage and precise pressure control are critical to ensure safety and system integrity. Whether used in solar farms, wind turbines, geothermal pipelines, or green hydrogen production, valve solutions for renewable energy systems must deliver consistent, reliable performance to support a cleaner, more sustainable future.

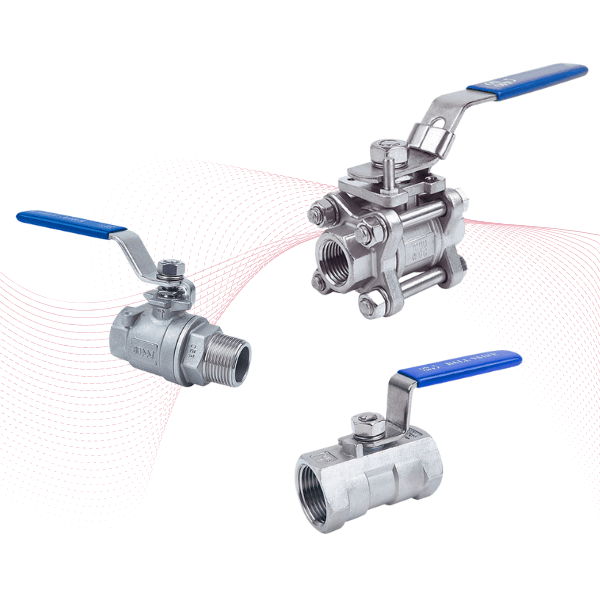

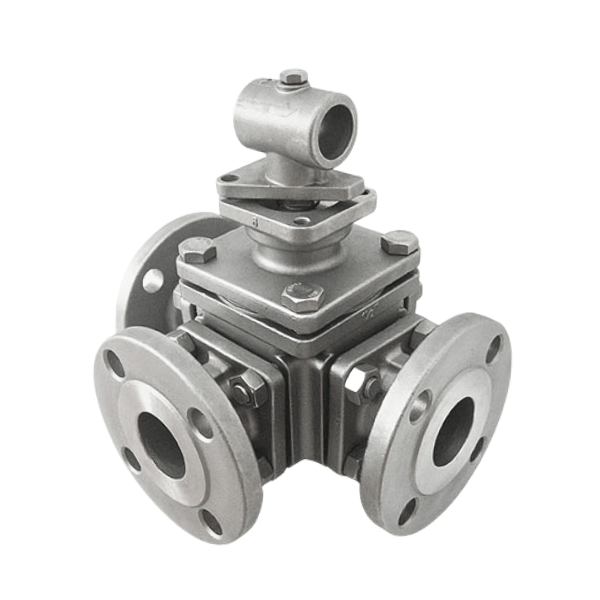

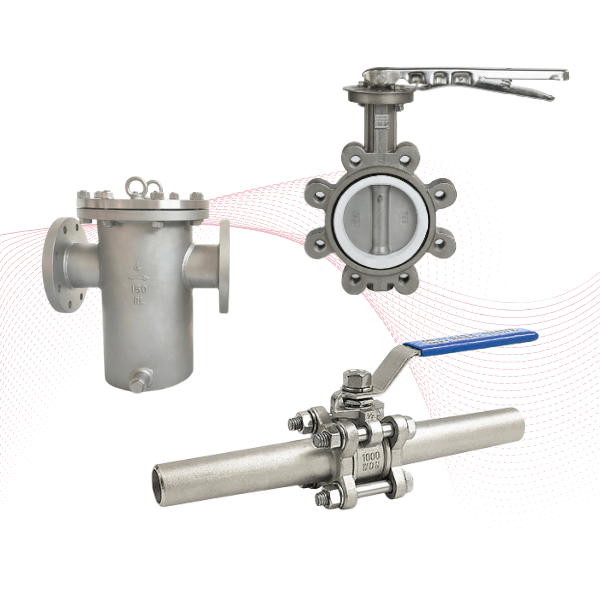

Stainless Steel Valves

VALTEK Solutions for Process ControlStainless steel valves for solar and wind power are essential for handling fluid transfer, cooling systems, and corrosive environments in solar farms, wind energy stations, and geothermal plants. Their resistance to chemical exposure and thermal variation ensures durability, minimizing downtime in renewable energy applications.

Stainlss Steel Ball Valve

VALTEK Solutions for Process ControlVALTEK's industrial valves for renewable energy plants, including stainless steel ball valves, offer precise control and long service life. They are ideal for solar thermal loops, wind turbine cooling, and hydrogen energy systems, where leak-tight sealing and corrosion resistance are non-negotiable.